HAREROD

Marcus Hasenstab - Dipl.-Ing. (FH) Electrical Engineering / Automation

Electronics - Firmware - Documentation

Technology

This page introduces the 'toolbox' HAREROD applies to work towards your success.Presented are prefered hard- and software products.

STM3232bit ARM Family of Microcontrollers - Hardware-/Firmware Development

AVR8bit-Family of Microcontrollers - Hardware-/Firmware Development

PIC8bit-Family of Microcontrollers - Hardware-/Firmware Development

ESP322.4 GHz Wi-Fi-and-Bluetooth combo chip

EAGLECADSOFT EAGLE PCB-Design-Software

TARGETIB Friedrich - Target 3001!

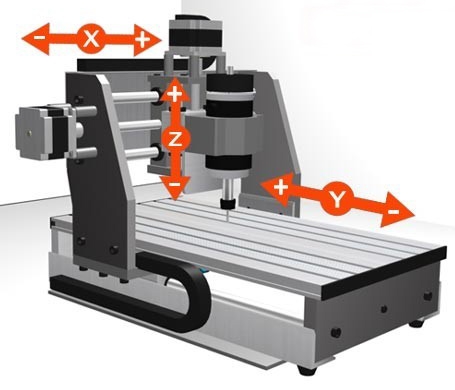

Mill RouterMicro CNC Mill Router

STM32 - 32bit ARM Family of Microcontrollers - Hardware-/Firmware Development

- wide spread platform for complex microcontroller applications

- on their own account ST Microelectronics claimed a 45% market share of Cortex-M microcontrollers by 2010

- for performance requirements between 8bit-controllers and embedded PCs

- is used at HAREROD for most current projects, because of

- high computing power reserves (up to 400MHz ARM Cortex-M7 with FPU and DSP)

- ample internal memory (up to 2MiB flash and 340KiB SRAM)

- cost reducing internal peripherals

- is used at HAREROD for most smaller current projects, because

- F0/Cortex M0 family provides low-cost, small MCUs (up to 48MHz ARM Cortex-M0)

- this allows one code base to be used for all classes of projects

- preferred development environment for RTOS-applications: CubeMX + FreeRTOS + lwIP

- well established codebase directly from the chip manufacturer

- stable codebase

- customer may take over the project at any time without additional cost

- any number of concurrent developers on the project

- preferred development environment is GCC and CMSIS

- Eclipse based development environment free available for commercial projects - e.g. CubeMX, Atollic TrueStudio and CooCox

- high guaranteed future use through lack of hardware protection ('dongle') and software leases

- customer may take over the project at any time without additional cost

- any number of concurrent developers on the project

- existing and tested own firmware modules, GCC and CMSIS based (selection)

- firmware framework

- often no operating system

- enables lean applications

- project-, data- and future-security through absolute control of the framework

- often no operating system

- watchdog and stack/heap guard for high reliability

- systemtimer

- system time base

- application timer

- RTC - Real Time Clock

- battery buffered real time clock - e.g. for data logger

- over 5 year operation from a CR2032 button cell

- backup-RAM e.g. for operating state storage

- interrupt handler

- DMA - Direct Memory Access

- main loop / scheduler

- LCD-graphics library

- framebuffer with overlay

- basic functions - pixel, line, arc

- arbitrary fonts - e.g. Windows or custom designs

- touch interface - with buttons, sliders, keyboard

- beeper-sound

- input of melodies via staves

- USART - Universal Synchronous Asynchronous Transceiver

- supports different serial interfaces e.g., RS232, RS485 (full- and half-duplex)

- Command Interpreter for remote control of the module

- typically 4..8 USARTs on-chip, possibility of additional external channels

- field firmware update

- USB - Universal Serial Bus

- application specific input devices

- HumanInterfaceDevice - keyboard, joystick, mouse with Windows standard driver

- emulation of a serial interface

- CommunicationDeviceClass - VirtualComPort with Windows drivers from ST

- field firmware update - DeviceFirmwareUpdate

- application specific input devices

- timer

- PWM - e.g. for motor control

- impulse generator - the STM32F4 features Timer with 168MHz clock rate

- beeper sound

- SPI - Serial Peripheral Interface

- sensor control

- IO-extension

- SDcard Interface via SPI or SDIO

- I2C - Inter Integrated Circuit

- EEPROM for parameter storage / Ethernet MAC

- sensor control

- ADC - Analog to Digital Converter

- module self diagnosis, including analog watchdog

- signal measurement

- touchpanel-interface (resistive, without external logic)

- DAC - Digital to Analog Converter

- programmable signal generator with 1MSps

- FMC - Flexible Memory Controller

- LCD - e.g. compatible to Toshiba T6963C or Epson SED1278

- SDRAM for memory demanding applications

- Ethernet

- several PHY and SWITCH variations

- mini-webserver as remote user interface

- web pages in internal flash memory or, e.g., on SDcard

- data exchange via Common Gateway Interface (CGI)

- simple data display using Server Side Includes (SSI)

- generation of dynamic content, e.g. show LCD-data as bitmap

- HTML-touchscreen-emulation

- identical user interface for browser and touch display

- firmware framework

- optimized schematics- and layout development due to familiarity with special features

- part selection

- pinout

- external circuitry

AVR - 8bit-Family of Microcontrollers - Hardware-/Firmware Development

- well established work horse for microcontroller applications

- long standing experience from uncountable projects

- beginning with the AT90S1200 up to ATmega164

- is used in current projects, if

- size is an issue (RFID-base station, melody generator)

- simplicity is required (hovering Christmas ball)

- very low cost is required

- even lower standby power than STM32L, e.g. < 1µA for newer ATtiny

- preferred development tools

- Atmel Studio with GCC

- short development times and good portability through high level C language

- Atmel Studio with AVR-Assembler

- selective usage of machine language yields crisp timing without external logic parts (MAHPONG)

- Atmel Studio with GCC

- optimized schematics- and layout development due to familiarity with special features

- part selection

- pinout

- external circuitry

PIC - 8bit-Family of Microcontrollers - Hardware-/Firmware Development

- well established work horse for microcontroller applications

- long standing experience from uncountable projects

- beginning with the PIC16C54 up to current PIC10/PIC12/PIC16F-types

- is used in current projects, if

- size is an issue

- very low power is available (LCD timer module)

- extra low cost is required (LCD timer module)

- preferred development tools

- Microchip MPLAB with MPASM

- usage of machine language yields very compact code and crisp timing without external logic parts (LCD timer module)

- Microchip MPLAB with MPASM

- optimized schematics- and layout development due to familiarity with special features

- part selection

- pinout

- external circuitry

ESP32 - 2.4 GHz Wi-Fi-and-Bluetooth combo chip

- Prolific System-on-Chip, integrating wireless functionality with a high performance microcontroller system

- IoT (Internet of Things)

- wireless webserver

- extensive integrated periphgeral set (extract)

- Wi-Fi Key Features

- 802.11 b/g/n

- 802.11 n (2.4 GHz), up to 150 Mbps

- BT Key Features

- Compliant with Bluetooth v4.2 BR/EDR and BLE specifications

- Class-1, class-2 and class-3 transmitter without external power amplifier

- CPU and Memory

- Xtensa single-/dual-core 32-bit LX6 microprocessor(s)

- Peripheral Interfaces

- Two timer groups, including 2 x 64-bit timers and 1 x main watchdog in each group

- One RTC timer

- RTC watchdog

- 34x programmable GPIOs

- 12-bit SAR ADC with up to 18 channels

- 2x 8-bit DAC

- 10x touch sensors

- 4x SPI

- 2x I2S

- 2x I2C

- 3x UART

- 1x host (SD/eMMC/SDIO)

- 1x slave (SDIO/SPI)/li>

- Ethernet MAC interface with dedicated DMA and IEEE 1588 support

- CAN 2.0

- IR (TX/RX)

- Motor PWM

- LED PWM up to 16 channels

- Hall sensor

- Wi-Fi Key Features

- Experience by reference projects with proven EN 60601 (medical) and ETSI EN 301 489 (radio) conformity

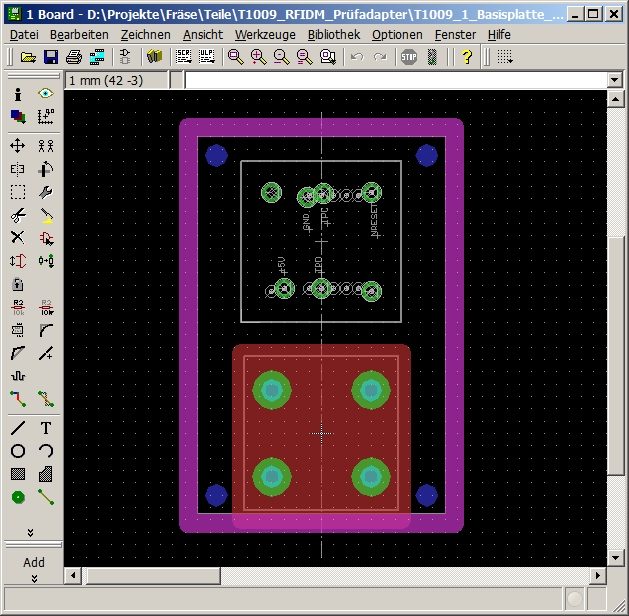

CADSOFT EAGLE PCB-Design-Software

- worldwide established design software for circuit design and PCB layout

- long standing experience from uncountable projects

- using version EAGLE 7 Professional, previous versions 4-6 Professional available, AutoDesk leased versions 8++ on customer's request

- free viewer application available to customers

- experiences with other packages (Mentor, Altium) are used for concepts of the workflow

- HAREROD parts database

- the parts database is maintained integrating constant feedback from our manufacturers

- proven design rules and packages guarantee high production yields

- unique part mapping by manufacturer codes

- production data preparation

- HAREROD production partners get explicit records, consisting of

- EAGLE BRD

- the reference for the PCB is the BRD-file, not secondary data like Gerber etc.

- the manufacturers are responsible for generation of CAM data fitting their processes

- bill of materials

- a basic bill of materials (BOM) is automatically generated from the parts database

- the BOM is fine tuned for the chosen manufacturer (prototypes/pilot runs/large-scale)

- module/component specifications/datasheet

- each module/component has its own specifications/datasheet

- definition of production processes

- EAGLE SCH

- the separation of PCB data and schematics protects customer know-how

- following corresponding agreements, schematics may be issued to the manufacturer to facilitate additional device tests

- EAGLE BRD

- HAREROD production partners get explicit records, consisting of

- the quality of HAREROD production data is being repeatedly complimented by manufacturing partners, resulting in customers to order reviewing and processing of data provided by third party developers

IB Friedrich - Target 3001!

- wide established design software for circuit design and PCB layout

- long standing experience from many projects

- free viewer application available to customers

- front panel design

- Target3001! contains a module for front panel design

- generation of mill- and print-data

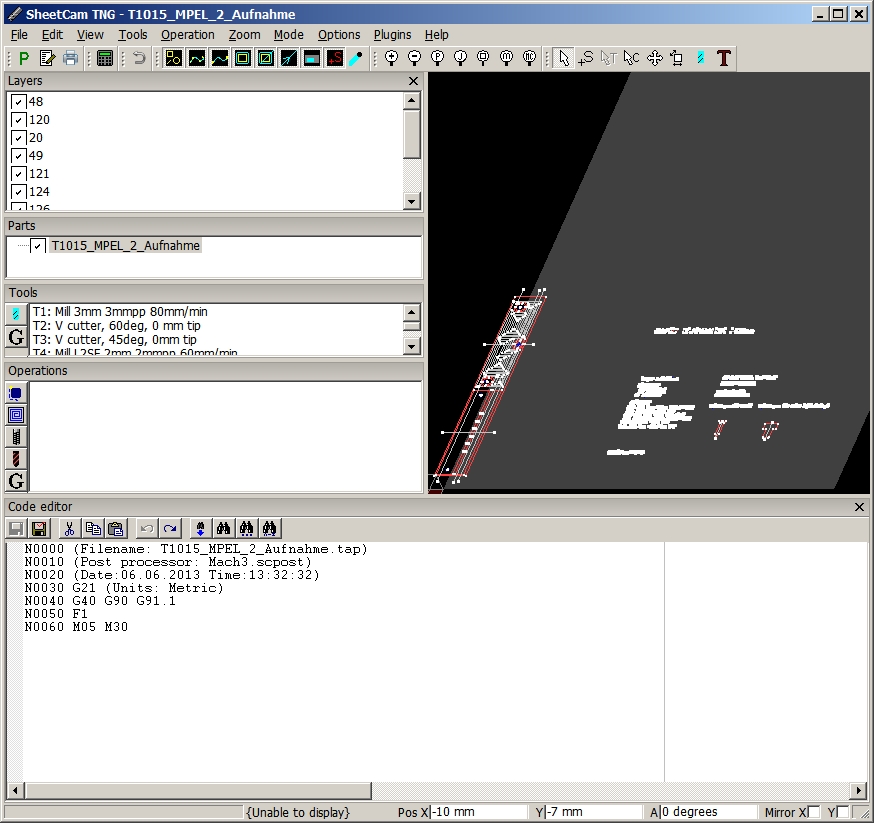

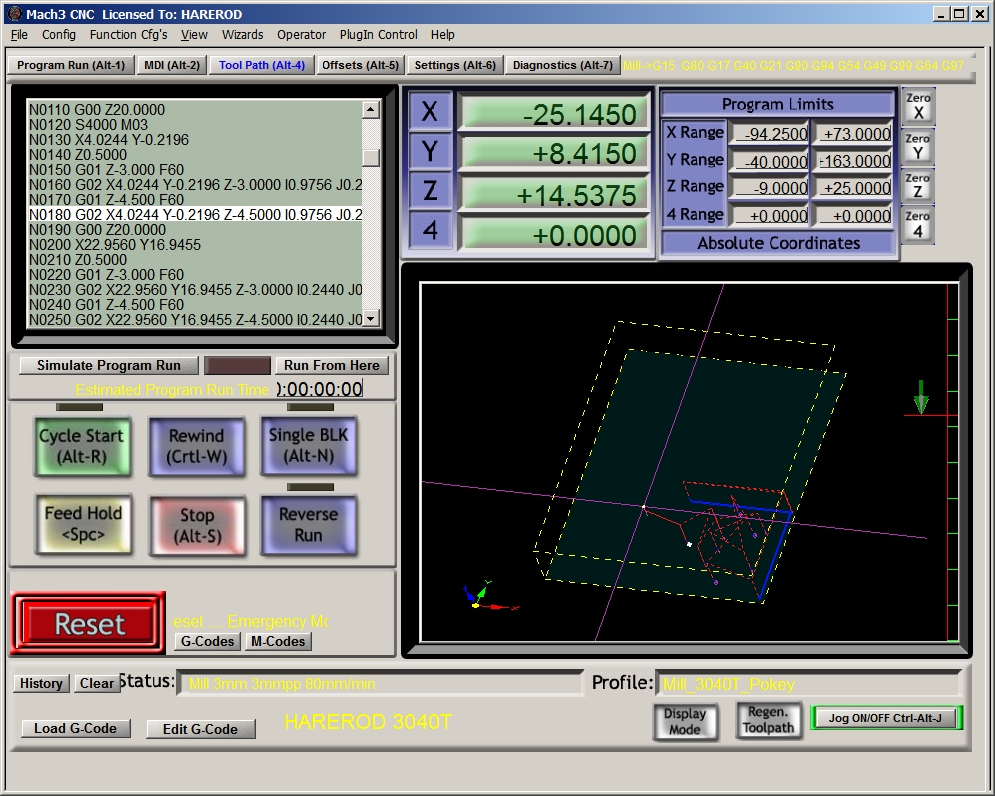

Micro CNC Mill Router

- a micro mill router can not replace industrial parts manufacturing

- a micro mill router enables cost optimized rapid prototyping and pilot runs without third-party manufacturing

- workflow

- design of DXF-drawings (e.g., EAGLE)

- translation of DXF into G-code (incl. tool informations)

- CNC processing

- router workspace

- ca. 500mm x 350mm x 70mm

- tools (selection)

- mill 0.3mm .. 3mm

- drill 0.5 .. 3mm

- engraver 45° / 60°

- preferred material

- POM - Polyoxymethylen

- physiologically uncritical

- high rigidity and stiffness

- thermoplast -40..130°C

- density 1.4g/ccm

- POM - Polyoxymethylen

- workflow

- lab samples

- ports in sample casings

- test equipment manufacturing

- test adapters / assembling calipers / programming adapters

- development and manufacturing parallel to the electronics development

- test adapters / assembling calipers / programming adapters

- reworking

- nearly no new design is bug free - the micro CNC mill allows manual or automated rework of PCB's, e.g.

- connector does not fit

- adjust drill diameter, e.g., with 0.5mm drill/mill

- layout bugs

- precision stripping of stop solder mask, to add patches

- precision stripping of PCB material to reach inner layers

- precison cutting of copper traces, e.g., with 0.5mm mill

- connector does not fit

- nearly no new design is bug free - the micro CNC mill allows manual or automated rework of PCB's, e.g.